Iván Hernández Dalas: Universal Robots partners with Robotiq and Siemens for smart palletizing

CES attendees can see the integration of a Universal Robots UR20 arm, Robotiq’s palletizing cell, and Siemens’ digital twin software. Source: Universal Robots

Universal Robots A/S and Robotiq Inc. yesterday unveiled a robotic palletizing system at CES 2026. The companies created the system in collaboration with Siemens AG.

The system combines Robotiq’s PAL Ready palletizing cell with Universal Robots’ UR20 force- and power-limited robot arm. They are integrated into Siemens’ automation hardware and the Digital Twin Composer software it launched at the event.

“Our work with Robotiq and Universal Robots exemplifies what can happen when you mix together advanced automation and real-time digital twins with the power of industrial AI,” stated Stuart McCutcheon, global vice president of sales and customer success at Siemens Digital Industries.

“Siemens is proud to collaborate with Universal Robots and Robotiq to bring the industrial metaverse to life at CES and demonstrate how manufacturers can truly innovate faster, optimize operations, and unlock new efficiencies,” he said.

System uses digital twins to improve real-world efficiency

Designed to support a company’s operational needs, the system palletizes boxes of chips and beverages. It uses digital twin analytics to optimize gripper performance and suction points dynamically.

“This collaboration with Universal Robots and Siemens demonstrates how lean palletizing, combined with cutting-edge digital twin technology, can help companies boost efficiency and adapt quickly to changing demands,” said Samuel Bouchard, CEO of Lévis, Canada-based Robotiq.

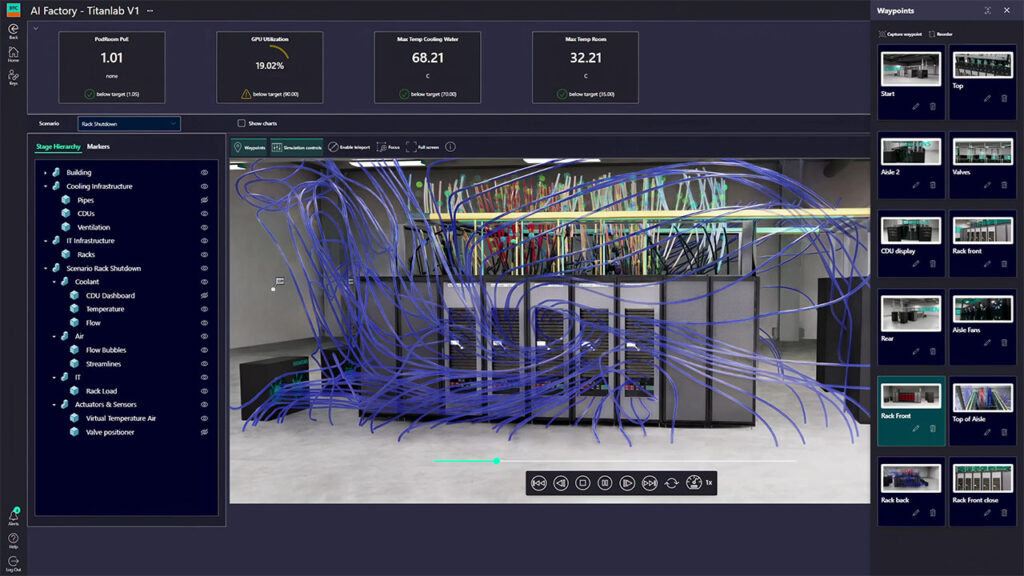

With data captured using Siemens’ Industrial Edge hardware and then streamed to its Insights Hub Copilot, the demonstrator provides real-time insights into cell behavior. The companies said this presents the scenario in a real-time photorealistic environment built using Siemens’ new Digital Twin Composer.

“The seamless integration of our heavy-duty UR20 robot with Robotiq’s palletizing cell and Siemens’ advanced automation and software shows how digital and physical innovation can work hand in hand to transform production environments and deliver measurable ROI,” said Jean-Pierre Hathout, president of Teradyne Robotics, the parent company of Universal Robots.

Siemens says Digital Twin Composer applies AI at scale

Siemens said its Digital Twin Composer builds industrial metaverse environments at scale. The company said the software empowers organizations to apply industrial AI, simulation, and real-time physical data to make decisions virtually, at speed, and at scale.

Digital Twin Composer enables industrial companies to combine 2D and 3D data from Siemens’ comprehensive digital twin with physical real-time information. It does this in a managed, secure, photorealistic visual scene, built using NVIDIA Omniverse libraries.

With Digital Twin Composer, Siemens said companies can rapidly build and maintain this global environment, containing all aspects of their product or production data (both virtual and physical). It does this in a secure, managed high-fidelity 3D experience throughout the lifecycle of the product, process, or facility.

Digital Twin Composer provides contextualized, real-time insights enabling companies to visualize, interact with, and iterate on any product, process, or factory in its real-world context before physical design or construction, added Siemens.

CES attendees can see the demonstration at Siemens’ booth, No. 8725 in the North Hall of the Las Vegas Convention Center.

The new Digital Twin Composer from Siemens builds Industrial Metaverse environments at scale. | Source: Siemens

The post Universal Robots partners with Robotiq and Siemens for smart palletizing appeared first on The Robot Report.

View Source